As a licensed, master electrician, I’m here to tell you everything you need to know about aluminum wiring in your house, including potential dangers and remedies. Many websites provide good information about aluminum wiring in houses, but it’s often impractical. Some high-ranking home inspector sites downplay the potential dangers, while insurance companies may exaggerate them. These are often written by individuals who may have never seen aluminum wiring, or any wiring, in person. As a master electrician with extensive experience in dealing with and replacing aluminum wiring throughout my career, I aim to offer a professional article on this topic. Read on to find out when aluminum wiring was commonly used, the potential dangers it poses, how to identify it, and the remedies available when dealing with homes that have aluminum wiring.

Why Does Aluminum Wire Fail?

Failures in aluminum wiring often occur at termination points, such as connections to circuit breakers, receptacles, or other devices. Typically, these failures are more common at receptacle terminations due to substandard connections. The root cause lies in the interaction between dissimilar metals, specifically aluminum wiring spliced to copper wiring, leading to electron flow discrepancies. Consequently, this mismatch results in overheating, wire expansion, oxidation, increased resistance, and eventual failure. Loose connections and arcing frequently ensue, ideally contained within the electrical box with a correctly sized breaker tripping.

Another contributing factor to aluminum wire failures is incorrect circuit breaker sizing. Unlike copper wire, aluminum wire has a lower ampere rating, which often leads to improper breaker replacements in electrical panels by those unfamiliar with it. Understanding these dynamics is crucial for ensuring the safety and reliability of electrical systems in homes.

How To Identify Aluminum Wiring

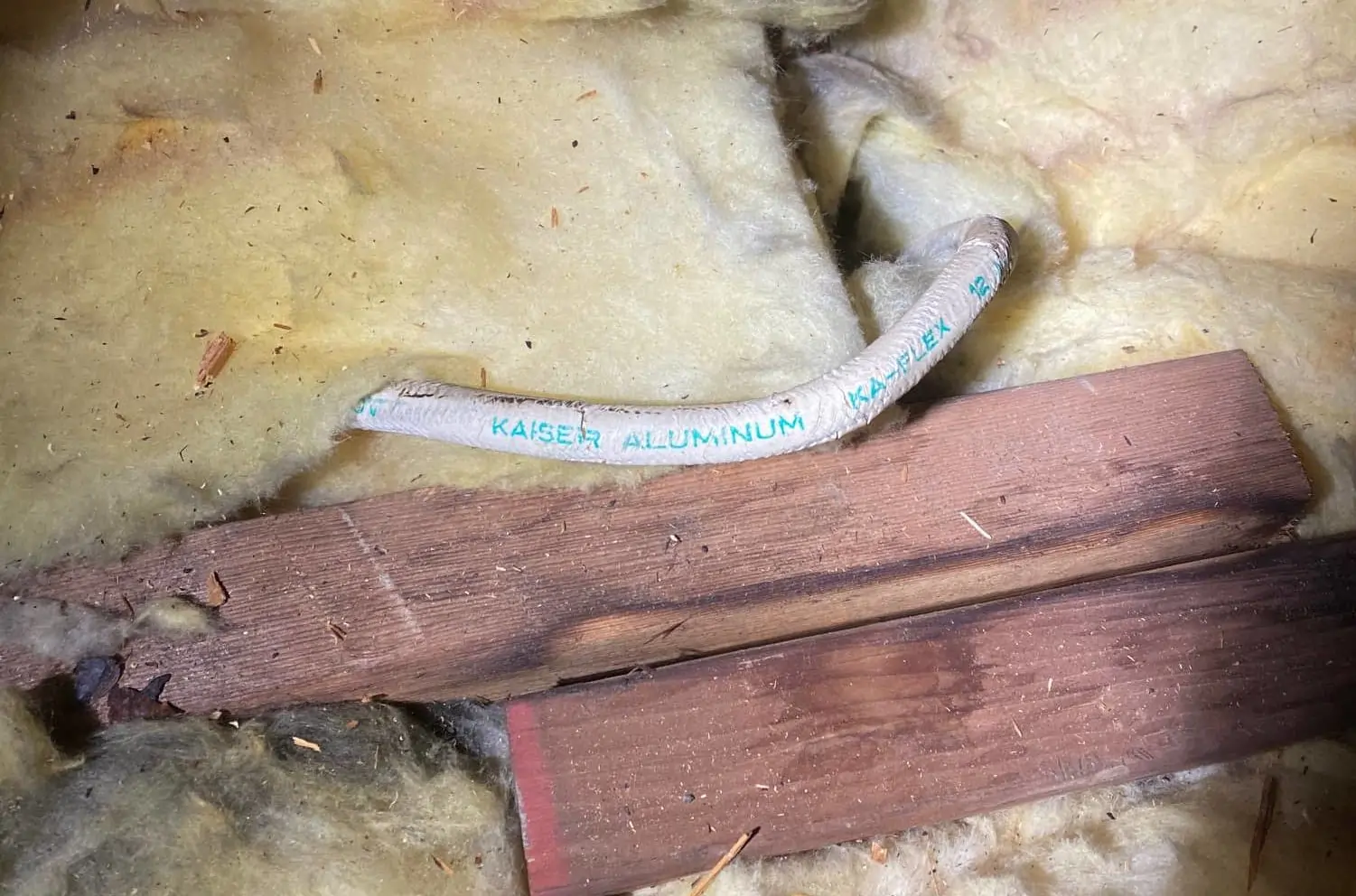

The outer jacket of aluminum wiring came in a few variants that I’ve seen. Most commonly, a white rubber jacket, sometimes a white braided cloth, and sometimes a black rubber jacket. If you have romex in an unfinished part of the home, you will be able to identify right off of the jacket to see if it is aluminum. DO NOT touch any of the wires, even if they look like they’re in good shape.

Here is what a white braided jacket looks like, note “Aluminum” written on the jacket:

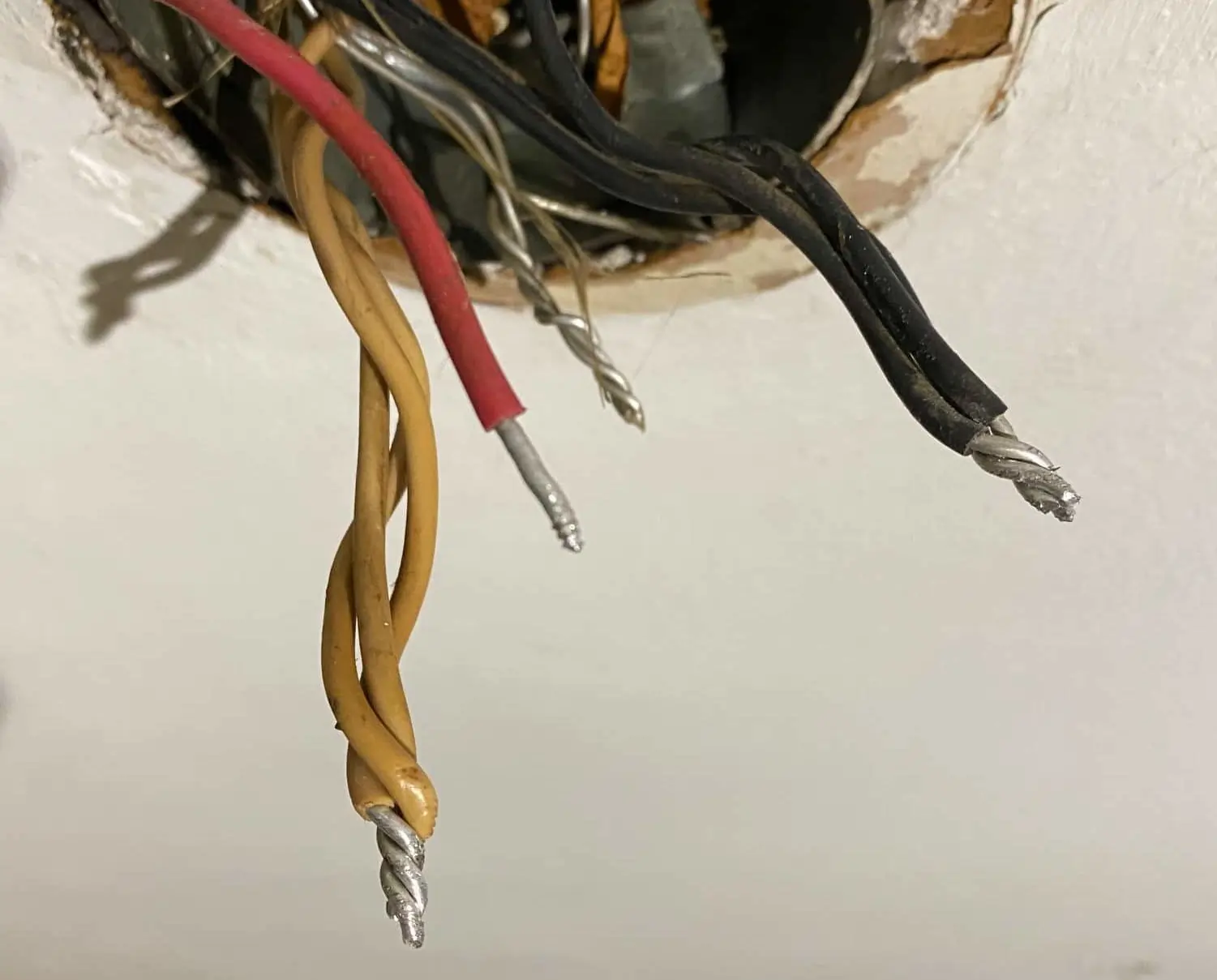

The actual conductors inside of the jacket look similar to copper conductors but when stripped (and not burned) exposes a bright, shiny aluminum. See below:

How to Properly Repair Aluminum Wire

The CPSC (Consumer Product Safety Commission) recommends the following as potential remedies:

1. Rewire the house/aluminum circuits

2. COPALUM crimps

3. Acceptable alternative methods (AlumiConn connectors, Ideal #65 wirenuts)

Let’s discuss these in more detail and explain what is involved with each of these aluminum wiring repair methods.

1. Rewiring the house:

By far the best solution and it honestly pains me to say so. If my house has aluminum wiring this is the path I would take. Like all things in life, the best solution here also tends to be the most costly because of the difficulty involved. It is the ONLY solution that results in absolute permanent repair in my opinion because the questionable electrical conductors are now out of the equation. If your home is a ranch style home with an unfinished basement or accessible attic, you’re in good shape. If your home is a split ranch type with no access below or above some of the rooms, the process is going to be more invasive and expensive. Drywall will most likely need to be removed in various locations for the new circuits to be installed. “You have to crack an egg to make an omelet”.

2. COPALUM crimps:

I’ll be subjective here, I don’t like this. In my years as a master electrician and remediating aluminum wiring (on Long Island we have lots of aluminum wired house) I’ve only met a few other contractors who have used the COPALUM crimp connector repair system in the past and do not continue to do so. COPALUM is a system created by Tyco Electronics in which one needs to take a class on how to do their “cold weld” and then rent a special machine that only they make.

At the time of writing this article, the COPALUM tool costs roughly $2000.00/month to rent because you can not purchase it outright. This does not include the cost of attending the training for an electrician to do COPALUM crimping plus the cost of the actual crimps. The crimping tool is cumbersome and does not always fit in to the work space where the repair is. The bottom line after all that is that you will still have aluminum wiring in the walls that could be an issue. From what I have seen, COPALUM is a fancy remedy claiming to be a permanent repair that makes no financial sense. Spend your money on new circuits if you were considering this route.

3a. AlumiConn Connectors:

Neat little devices that allow you to essentially pig tail the aluminum wire to a new copper wire without having to twist the wires together in the traditional way. This puts less stress on the aluminum wires when they’re being handled but the connectors and wiring will still need to be folded in to the box which again will put stress on the wires. Another interesting note is that many report that they can not adequately tighten the screws which need a very specific 10in-lbs or 15in-lbs depending on the wire size. The instructions recommend a torque screw driver or a specific amount of turns once contact with the conductor is made under the screw.

3b. Ideal #65 Wire Nuts:

While the official CPSC Publication 516 does not specifically list Ideal Copper-Aluminum (#65) wire nuts, UL lists them for temporary repair of aluminum wiring. Proponents of COPALUM and other CPSC-approved methods tend to ignore the existence of copper-aluminum wire nuts. According to Ideal, these wire nuts provide a safe, effective, legal, and permanent solution to the problem of connecting copper conductors to existing aluminum branch circuit wiring when used in accordance with the included instructions.

The IDEAL Model #65 TWISTER® AL/CU Connector complies with N.E.C. Section 110-14b for aluminum to copper connections and Federal Specification W-S- 610E. It is UL 486C Listed, UL 467 Listed, UL 94V-2 flame rated, CSA C22.2 #188 Certified, and rated 105°C (221°F) for use in all branch circuit and fixture splicing applications. They are technically listed for permanent repair. I have performed numerous aluminum wiring repairs by pig-tailing with Ideal #65’s, but I have also seen instances of failure. I cannot speak to the installation methods used, but these instances have definitely shifted my perspective on them.

Is Aluminum Wiring Safe?

If you’ve researched home electrical wiring and safety, you’ve likely encountered differing opinions on aluminum wiring. Price comparisons between aluminum and copper wire for projects might also have influenced your decisions.

Stranded aluminum wiring of 8 AWG or larger is safe for home electrical wiring. However, the solid aluminum wire commonly used for standard 15-20 amp circuits in the 1960s and 70s poses a fire hazard and raises concerns.

Despite its bad reputation in remodeling resources, the truth about aluminum wire is more complex. When used appropriately, aluminum performs comparably to copper and can offer substantial cost savings.

Consequences, and Closing Thoughts:

I need to REALLY emphasize the importance of hiring a licensed, experienced, professional electrician when dealing with aluminum wiring should you have it repaired via one of the above methods. I have too frequently seen the aluminum “repairs” fail because of improper attempted repair. If someone has spliced copper on to the aluminum at any point in the past there is a VERY high chance it will at the least overheat and melt.

Thanks for reading. Feel free to contact us for more information or with questions on our contact form and check our official National Electrical Registry for a licensed electrical contractor near you that can help you with remediating aluminum wiring.

References:

- https://minerals.usgs.gov/minerals/pubs/commodity/copper/240798.pdf

- https://www.cpsc.gov/s3fs-public/516.pdf

- http://www.idealindustries.ca/media/pdfs/products/twister_al-cu_compliance.pdf

- http://www.structuretech1.com/wp-content/uploads/2012/10/Reducing-Hazards-with-Aluminum-Wiring.pdf

Aluminum wiring was used in home building roughly between the years of 1968-1973.

In short, aluminum wiring is much more prone to overheating and causing fires and needs to be remediated or replaced.

Yes, however the aluminum wiring used today is different and typically used for large applications such as the service entrance conductors. Don’t confuse this with branch circuit wiring of the 60’s and 70’s that were aluminum.